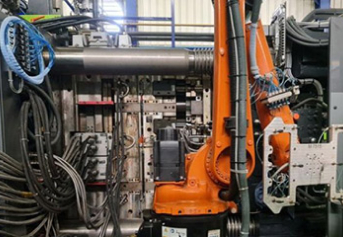

Injection Molding

GLN Advanced Solutions has the top brand injection molding machines, using several molding techniques to meet the needs of the automotive market.

Equipped with more than 80 machines with mold clamping forces ranging from 25 to 700 tons, using a wide variety of technologies:

molding

technology

molding

labelling

molding

decoration

technologies

molding

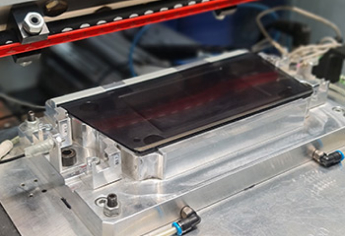

Surface finishing technologies

GLN Advanced Solutions is well recognized by the automotive plastic decorative components clients serving the most demanding brands.

Equipped with 6 lines of fully automatic painting equipment able to apply water-based and solvent-based paints, piano black high gloss, metal-like decorations and clear UV cure varnish.

Other complementary decorations are available such as: pad printing, hot stamping, silk screening, and laser etching finishings.

GLN Advanced Solutions is vertically integrated to produce decorative 3D foil forming and overmolding.

Chrome-plated parts based on referenced sub-suppliers are also included in our product portfolio.

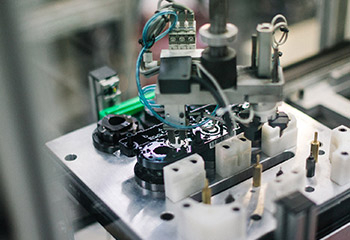

Assembly Equipment

GLN Advanced Solutions has expertise in assembling complex parts ensuring high-quality through the usage of several joint techniques always looking for cost effectiveness and robust on-line control technologies and traceability.

vibration

welding

flexible lines

assembly

testing